日本佑能UNNION避空型圆角刀CRRS系列4刃硬

品牌:UNION(佑能)

型号:G5ACB32B40B2DD

¥待询价(提交订单10分钟内获取专属报价单)

| 加工材料 | |||||||||||||||

| 碳素钢 S45C S55C | 合金钢 SK/SCM SUS | 预硬钢 NAK HPM | 淬火钢 | 铸铁 | 铝合金 | 石墨 | 铜 | 树脂 | 玻璃纤维 树脂 | 钛合金 | 高温合金 | 超硬合金 | 硬脆材料 | ||

| ~55HRC | ~60HRC | ~70HRC | |||||||||||||

| ◎ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ | ◎ | |||||||

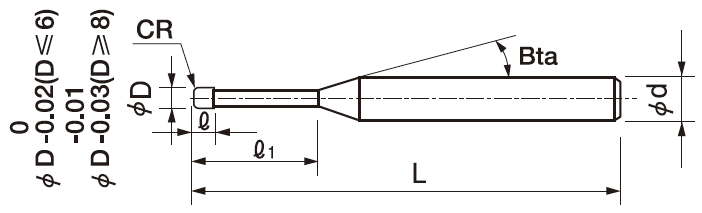

| 型号 | 直径 φD | 圆角半径 CR | 有效长 R1 | 刃长 R | 首径 φd1 | 柄锥角度 Bta | 全长 L | 柄径 φd |

| CRRS 4020-05-06 | 2 | R0.5 | 6 | 2 | 1.91 | 16° | 70 | 4 |

| CRRS 4030-08-09 | 3 | R0.8 | 9 | 3 | 2.92 | 16° | 70 | 6 |

| CRRS 4040-03-12 | 4 | R0.3 | 12 | 4 | 3.82 | 16° | 60 | 6 |

| CRRS 4040-05-12-4 | R0.5 | — | 70 | 4 | ||||

| CRRS 4040-05-12 | 16° | 60 | 6 | |||||

| CRRS 4040-10-12-4 | R1.0 | — | 70 | 4 | ||||

| CRRS 4040-10-12 | 16° | 70 | 6 | |||||

| CRRS 4050-12-15 | 5 | R1.2 | 15 | 5 | 4.82 | 16° | 70 | 6 |

| CRRS 4060-03-18 | 6 | R0.3 | 18 | 6 | 5.82 | — | 90 | 6 |

| CRRS 4060-05-18 | R0.5 | 60 | 6 | |||||

| CRRS 4060-10-18 | R1.0 | 60 | 6 | |||||

| CRRS 4060-15-18 | R1.5 | 90 | 6 | |||||

| CRRS 4080-03-24 | 8 | R0.3 | 24 | 8 | 7.82 | — | 100 | 8 |

| CRRS 4080-05-26 | R0.5 | 26 | 70 | 8 | ||||

| CRRS 4080-10-26 | R1.0 | 70 | 8 | |||||

| CRRS 4080-20-24 | R2.0 | 24 | 100 | 8 | ||||

| CRRS 4100-03-30 | 10 | R0.3 | 30 | 10 | 9.82 | — | 110 | 10 |

| CRRS 4100-05-30 | R0.5 | 80 | 10 | |||||

| CRRS 4100-10-30 | R1.0 | 80 | 10 | |||||

| CRRS 4100-20-30 | R2.0 | 110 | 10 | |||||

| CRRS 4120-03-36 | 12 | R0.3 | 36 | 12 | 11.82 | — | 120 | 12 |

| CRRS 4120-05-36 | R0.5 | 120 | 12 | |||||

| CRRS 4120-10-36 | R1.0 | 120 | 12 | |||||

| CRRS 4120-20-36 | R2.0 | 120 | 12 |

| 加工材料 | 碳素钢 S45C/S55C (~225HB) | 合金钢 SK/SCM/SUS(225~325HB) 注:不锈钢加工推荐使用切削液 | 预硬钢/淬火钢 NAK/HPM/SKD/SKT/ STAVAX(30~55HRC) 注:推荐使用油雾 | |||||||||||

| 型号 | 直径 (mm) | 圆角半径 (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| 4020-05-06 | 2 | R0.5 | 30,000 | 7,200 | 0.08 | 0.8 | 30,000 | 7,200 | 0.04 | 0.66 | 24,000 | 7,000 | 0.02 | 0.59 |

| 4030-08-09 | 3 | R0.8 | 20,000 | 8,400 | 0.09 | 1.2 | 20,000 | 7,200 | 0.04 | 1.08 | 16,000 | 7,000 | 0.04 | 0.88 |

| 4040-03-12 | 4 | R0.3 | 15,000 | 9,600 | 0.09 | 1.6 | 15,000 | 7,200 | 0.05 | 1.32 | 12,000 | 7,000 | 0.05 | 1.17 |

| 4040-05-12-4 | R0.5 | 15,000 | 9,600 | 0.1 | 1.6 | 15,000 | 7,200 | 0.05 | 1.35 | 12,000 | 7,000 | 0.05 | 1.26 | |

| 4040-05-12 | 15,000 | 9,600 | 0.1 | 1.6 | 15,000 | 7,200 | 0.05 | 1.35 | 12,000 | 7,000 | 0.05 | 1.26 | ||

| 4040-10-12-4 | R1 | 15,000 | 9,600 | 0.11 | 1.6 | 15,000 | 7,200 | 0.05 | 1.53 | 12,000 | 7,000 | 0.06 | 1.33 | |

| 4040-10-12 | 15,000 | 9,600 | 0.11 | 1.6 | 15,000 | 7,200 | 0.05 | 1.53 | 12,000 | 7,000 | 0.06 | 1.33 | ||

| 4050-12-15 | 5 | R1.2 | 12,000 | 10,800 | 0.13 | 2 | 12,000 | 7,200 | 0.06 | 1.8 | 9,600 | 6,300 | 0.06 | 1.54 |

| 4060-03-18 | 6 | R0.3 | 10,000 | 12,000 | 0.13 | 2.4 | 10,000 | 7,200 | 0.07 | 1.94 | 8,000 | 5,250 | 0.07 | 1.63 |

| 4060-05-18 | R0.5 | 10,000 | 12,000 | 0.14 | 2.4 | 10,000 | 7,200 | 0.07 | 1.98 | 8,000 | 5,250 | 0.07 | 1.75 | |

| 4060-10-18 | R1 | 10,000 | 12,000 | 0.15 | 2.4 | 10,000 | 7,200 | 0.07 | 2.16 | 8,000 | 5,250 | 0.08 | 1.75 | |

| 4060-15-18 | R1.5 | 10,000 | 12,000 | 0.17 | 2.4 | 10,000 | 7,200 | 0.08 | 2.34 | 8,000 | 5,250 | 0.11 | 1.75 | |

| 4080-03-24 | 8 | R0.3 | 7,500 | 12,000 | 0.17 | 2.86 | 7,500 | 7,200 | 0.08 | 2.76 | 6,000 | 4,100 | 0.15 | 1.77 |

| 4080-05-26 | R0.5 | 7,500 | 12,000 | 0.18 | 2.64 | 7,500 | 7,200 | 0.08 | 2.61 | 6,000 | 4,100 | 0.14 | 1.76 | |

| 4080-10-26 | R1 | 7,500 | 12,000 | 0.18 | 2.72 | 7,500 | 7,200 | 0.09 | 2.7 | 6,000 | 4,100 | 0.16 | 1.76 | |

| 4080-20-24 | R2 | 7,500 | 12,000 | 0.22 | 2.88 | 7,500 | 7,200 | 0.1 | 2.79 | 6,000 | 4,100 | 0.18 | 1.96 | |

| 4100-03-30 | 10 | R0.3 | 6,000 | 12,000 | 0.2 | 3.04 | 5,000 | 5,400 | 0.14 | 2.82 | 4,800 | 4,100 | 0.18 | 1.89 |

| 4100-05-30 | R0.5 | 6,000 | 12,000 | 0.22 | 3.04 | 5,000 | 5,400 | 0.14 | 2.88 | 4,800 | 4,100 | 0.18 | 2.03 | |

| 4100-10-30 | R1 | 6,000 | 12,000 | 0.24 | 3.28 | 5,000 | 5,400 | 0.14 | 2.97 | 4,800 | 4,100 | 0.19 | 2.1 | |

| 4100-20-30 | R2 | 6,000 | 12,000 | 0.26 | 3.44 | 5,000 | 5,400 | 0.14 | 3.06 | 4,800 | 4,100 | 0.2 | 2.45 | |

| 4120-03-36 | 12 | R0.3 | 5,000 | 12,000 | 0.21 | 3.32 | 3,000 | 4,320 | 0.18 | 2.9 | 4,000 | 4,100 | 0.19 | 2.15 |

| 4120-05-36 | R0.5 | 5,000 | 12,000 | 0.24 | 3.32 | 3,000 | 4,320 | 0.18 | 2.96 | 4,000 | 4,100 | 0.19 | 2.32 | |

| 4120-10-36 | R1 | 5,000 | 12,000 | 0.26 | 3.59 | 3,000 | 4,320 | 0.18 | 3.06 | 4,000 | 4,100 | 0.2 | 2.4 | |

| 4120-20-36 | R2 | 5,000 | 12,000 | 0.28 | 3.76 | 3,000 | 4,320 | 0.18 | 3.15 | 4,000 | 4,100 | 0.21 | 2.8 | |

| 加工材料 | 碳素钢 S45C/S55C (~225HB) | 合金钢 SK/SCM/SUS(225~325HB) 注:不锈钢加工推荐使用切削液 | 预硬钢/淬火钢 NAK/HPM/SKD/SKT/ STAVAX(30~55HRC) 注:推荐使用油雾 | |||||||||||

| 型号 | 直径 (mm) | 圆角半径 (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| 4020-05-06 | 2 | R0.5 | 30,000 | 1,720 | 0.1 | 0.06 | 30,000 | 1,510 | 0.05 | 0.05 | 24,000 | 1,070 | 0.05 | 0.04 |

| 4030-08-09 | 3 | R0.8 | 20,000 | 1,890 | 0.1 | 0.09 | 20,000 | 1,660 | 0.05 | 0.08 | 16,000 | 1,160 | 0.05 | 0.07 |

| 4040-03-12 | 4 | R0.3 | 15,000 | 1,050 | 0.1 | 0.07 | 15,000 | 910 | 0.05 | 0.06 | 12,000 | 620 | 0.05 | 0.05 |

| 4040-05-12-4 | R0.5 | 15,000 | 1,360 | 0.1 | 0.09 | 15,000 | 1,180 | 0.05 | 0.08 | 12,000 | 810 | 0.05 | 0.07 | |

| 4040-05-12 | 15,000 | 1,360 | 0.1 | 0.09 | 15,000 | 1,180 | 0.05 | 0.08 | 12,000 | 810 | 0.05 | 0.07 | ||

| 4040-10-12-4 | R1 | 15,000 | 1,920 | 0.1 | 0.13 | 15,000 | 1,670 | 0.05 | 0.11 | 12,000 | 1,150 | 0.05 | 0.1 | |

| 4040-10-12 | 15,000 | 1,920 | 0.1 | 0.13 | 15,000 | 1,670 | 0.05 | 0.11 | 12,000 | 1,150 | 0.05 | 0.1 | ||

| 4050-12-15 | 5 | R1.2 | 12,000 | 1,910 | 0.1 | 0.16 | 12,000 | 1,630 | 0.05 | 0.14 | 9,600 | 1,120 | 0.05 | 0.12 |

| 4060-03-18 | 6 | R0.3 | 10,000 | 890 | 0.2 | 0.09 | 10,000 | 760 | 0.1 | 0.08 | 8,000 | 510 | 0.1 | 0.06 |

| 4060-05-18 | R0.5 | 10,000 | 1,150 | 0.2 | 0.12 | 10,000 | 990 | 0.1 | 0.1 | 8,000 | 670 | 0.1 | 0.08 | |

| 4060-10-18 | R1 | 10,000 | 1,630 | 0.2 | 0.16 | 10,000 | 1,400 | 0.1 | 0.14 | 8,000 | 950 | 0.1 | 0.12 | |

| 4060-15-18 | R1.5 | 10,000 | 2,000 | 0.2 | 0.2 | 10,000 | 1,720 | 0.1 | 0.17 | 8,000 | 1,170 | 0.1 | 0.15 | |

| 4080-03-24 | 8 | R0.3 | 7,500 | 1,170 | 0.2 | 0.11 | 7,500 | 1,050 | 0.1 | 0.09 | 6,000 | 720 | 0.1 | 0.08 |

| 4080-05-26 | R0.5 | 7,500 | 990 | 0.2 | 0.13 | 7,500 | 860 | 0.1 | 0.11 | 6,000 | 580 | 0.1 | 0.1 | |

| 4080-10-26 | R1 | 7,500 | 1,410 | 0.2 | 0.19 | 7,500 | 1,210 | 0.1 | 0.16 | 6,000 | 830 | 0.1 | 0.14 | |

| 4080-20-24 | R2 | 7,500 | 1,990 | 0.2 | 0.27 | 7,500 | 1,720 | 0.1 | 0.23 | 6,000 | 1,170 | 0.1 | 0.2 | |

| 4100-03-30 | 10 | R0.3 | 6,000 | 720 | 0.2 | 0.12 | 5,000 | 510 | 0.1 | 0.1 | 4,800 | 400 | 0.1 | 0.08 |

| 4100-05-30 | R0.5 | 6,000 | 940 | 0.2 | 0.16 | 5,000 | 660 | 0.1 | 0.13 | 4,800 | 520 | 0.1 | 0.11 | |

| 4100-10-30 | R1 | 6,000 | 1,330 | 0.2 | 0.22 | 5,000 | 940 | 0.1 | 0.19 | 4,800 | 740 | 0.1 | 0.15 | |

| 4100-20-30 | R2 | 6,000 | 1,890 | 0.2 | 0.32 | 5,000 | 1,340 | 0.1 | 0.27 | 4,800 | 1,050 | 0.1 | 0.22 | |

| 4120-03-36 | 12 | R0.3 | 5,000 | 680 | 0.2 | 0.14 | 3,000 | 330 | 0.1 | 0.1 | 4,000 | 360 | 0.1 | 0.09 |

| 4120-05-36 | R0.5 | 5,000 | 880 | 0.2 | 0.18 | 3,000 | 430 | 0.1 | 0.14 | 4,000 | 480 | 0.1 | 0.12 | |

| 4120-10-36 | R1 | 5,000 | 1,240 | 0.2 | 0.24 | 3,000 | 610 | 0.1 | 0.2 | 4,000 | 680 | 0.1 | 0.16 | |

| 4120-20-36 | R2 | 5,000 | 1,760 | 0.2 | 0.35 | 3,000 | 870 | 0.1 | 0.29 | 4,000 | 960 | 0.1 | 0.24 | |

| 突出长 L/D | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| L/D≤6 | ×1 | ×1 | ×1 | ×1 |

| L/D=7 | ×0.8 | ×0.8 | ×0.8 | ×0.9 |

| L/D=8 | ×0.7 | ×0.7 | ×0.7 | ×0.9 |

| L/D=9 | ×0.7 | ×0.7 | ×0.6 | ×0.8 |

| L/D=10 | ×0.6 | ×0.6 | ×0.6 | ×0.7 |

| 突出长 L/D | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| L/D≤4 | ×1 | ×1 | ×1 | ×1 |

| L/D=5 | ×0.9 | ×0.8 | ×0.9 | ×0.9 |

| L/D=6 | ×0.8 | ×0.7 | ×0.8 | ×0.9 |

| L/D=7 | ×0.7 | ×0.6 | ×0.6 | ×0.8 |

| L/D=8 | ×0.5 | ×0.4 | ×0.6 | ×0.7 |

| 突出长 L/D | 转速 (min-1) | 进给 (mm/min) | ap (mm) | ae (mm) |

| L/D≤4 | ×1 | ×1 | ×1 | ×1 |

| L/D=5 | ×0.7 | ×0.6 | ×0.6 | ×0.8 |

| L/D=6 | ×0.5 | ×0.4 | ×0.5 | ×0.7 |

思诚资源为您提供:日本佑能UNNION避空型圆角刀CRRS系列4刃硬质合金铣刀涂层的采购报价、UNION(佑能)G5ACB32B40B2DD型号参数、规格图片、PDF画册等资料,如您想了解更多关于UNION(佑能)正品品牌的其他圆角刀资料与产品货期库存、行情价格,就在思诚资源MRO商城。

备注:因厂家会在没有任何提前通知的情况下更改产品包装、产地或者一些附件,本公司不能确保客户收到的货物与思诚资源网站提供的产品图片、产地、附件说明等完全一致。若本网站没有及时更新,敬请谅解!